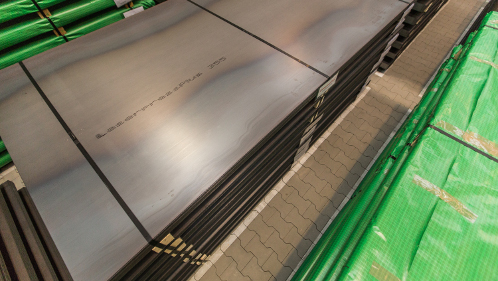

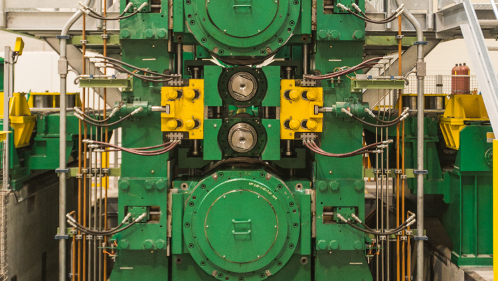

Our exclusive and patented in-line Skin-pass process improves shape, provides greater thickness control, produces a more desirable surface finish and eliminates internal stress memories of hot rolled sheets. ![]() LaserpressPlus® quality can improve productivity up to 30%.

LaserpressPlus® quality can improve productivity up to 30%.

Advantages for plasma and laser cutting:

Minimal burr on the cutting side.

Advantages for automatic bending, stamping and punching:

LaserpressPlus® 460

LaserpressPlus® 460

The modern steel processing industry requires the use of the most up-to-date technologies. Today, steel sheets should not only be stress free, but also need to have a superior degree of flatness and should be easy to handle during the cold transforming process.

In order to live up to these demands, Van Heyghen Stal Polska has developed a new quality:

![]() LaserpressPlus®. Its fine grained structure, high yield point and guaranteed flatness tolerance of 3mm/m up to

LaserpressPlus®. Its fine grained structure, high yield point and guaranteed flatness tolerance of 3mm/m up to ![]() LaserpressPlus® 460 and a guaranteed flatness of ½ EN on higher tensile steels ensure that this quality can meet the harshest quality criteria. The use of our

LaserpressPlus® 460 and a guaranteed flatness of ½ EN on higher tensile steels ensure that this quality can meet the harshest quality criteria. The use of our ![]() LaserpressPlus® quality can lead to a productivity gain of over 30%.

LaserpressPlus® quality can lead to a productivity gain of over 30%. ![]() LaserpressPlus® is achieved by our exclusive in line skin-pass, which eliminates all internal stress, improves shape, provides greater thickness control and produces a more desirable surface finish. Moreover, it corrects the shape of hot rolled sheets and plates, combining continuous cold reduction with corrective levelling equipment. Consequently, we can guarantee a constant and measured elongation of the full sheet thickness. This unique way of producing ensures an unchallengeable supreme result!

LaserpressPlus® is achieved by our exclusive in line skin-pass, which eliminates all internal stress, improves shape, provides greater thickness control and produces a more desirable surface finish. Moreover, it corrects the shape of hot rolled sheets and plates, combining continuous cold reduction with corrective levelling equipment. Consequently, we can guarantee a constant and measured elongation of the full sheet thickness. This unique way of producing ensures an unchallengeable supreme result!

![]() LaserpressPlus® exists in various qualities of hot rolled steel, pickled or unpickled, with trimmed or with mill edges.

LaserpressPlus® exists in various qualities of hot rolled steel, pickled or unpickled, with trimmed or with mill edges.